Products

Reliable Jaw Plates Suppliers for Crushers

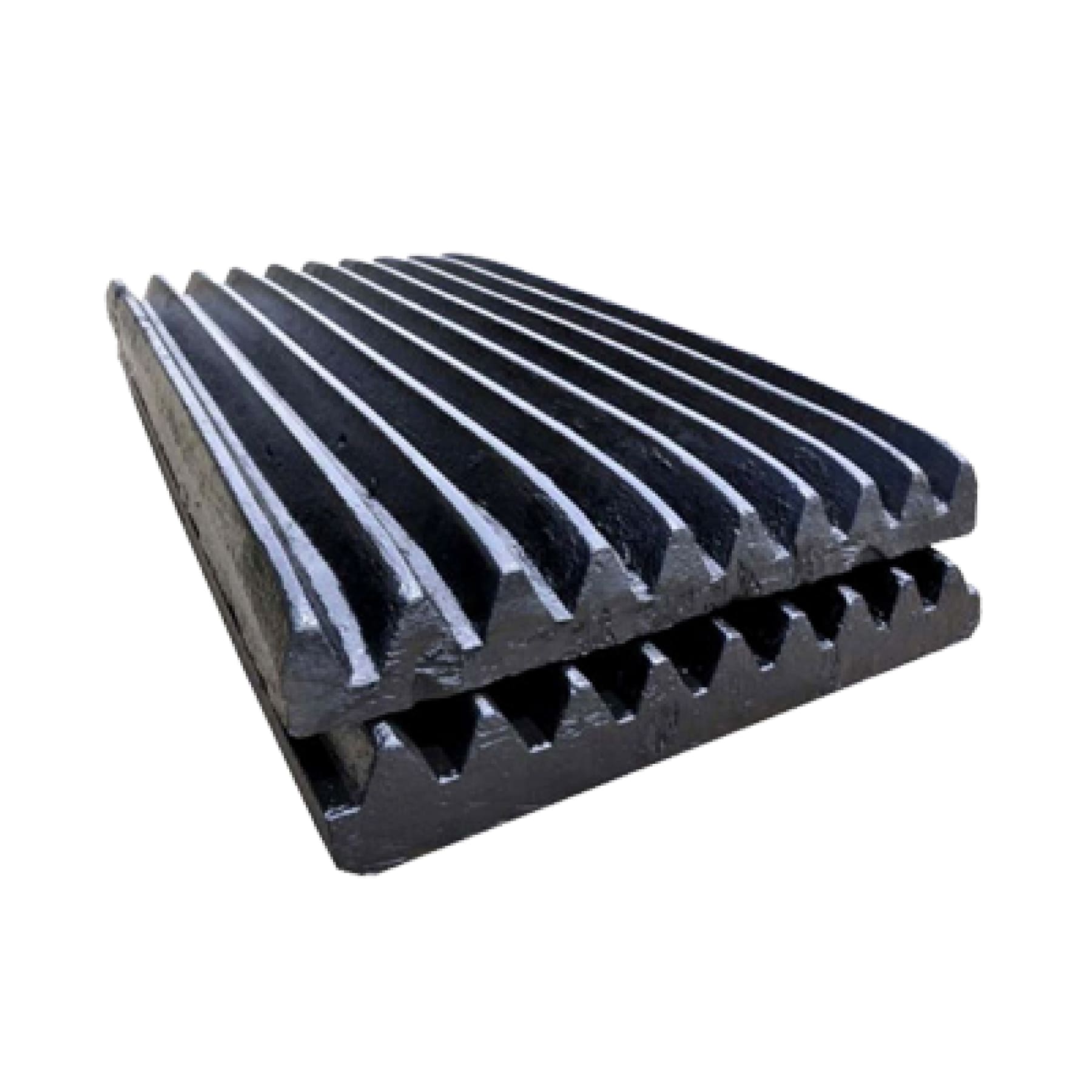

Jaw plates, often called tooth plates, are essential wear-resistant parts used in jaw crushers. These crushers play a key role in primary crushing, especially in cement plants and mining operations, where they handle the hardest materials and largest particles in production lines. A jaw crusher plate is a crucial component of a jaw crusher machine. Jaw plates suppliers typically provide different materials for the inner and outer parts of the jaw plates, depending on the specific needs and preferences of the customers.

Our jaw plates are crafted from advanced composite materials, primarily high manganese steel, a trusted choice for its toughness and ability to harden under impact. We offer various grades, including Mn13, Mn13Cr2, Mn18Cr2 (ultra-high manganese), and custom compositions tailored to specific operating conditions.

| Parameter | Specification |

|---|---|

| Material | High manganese steel |

| Length | As per Requirement |

| Width | As per Requirement |

| Thickness | As per Requirement |

| Usage | crushing and breaking big or large coal in the first step of a coal crushing plant |

| Capacity | As per Requirement |

Durable jaw plates are vital components of jaw crushers, engineered to withstand the demanding conditions of heavy-duty crushing operations and reduce maintenance costs. Jaw plates suppliers provide high-quality, durable jaw plates that offer several benefits.

- High Durability: Withstands harsh cement conditions.

- Optimized Design: Ensures better material flow.

- Strength-to-Weight Ratio: Lightweight yet highly durable.

- Reduced Maintenance: Fewer replacements required.

- Cost Savings: Lowers maintenance and expenses.

- Energy Efficiency: Optimizes energy consumption effectively.

- Material Quality: Delivers consistent product output.

Jaw Plate stands as a cornerstone in the construction industry, providing the necessary firepower to crush rocks and stones into usable materials. Understanding its role and applications is vital for professionals in the construction and mining sectors.

- Building Construction: Breaks concrete, bricks, and stones.

- Mining Industry: Crushes ores for material refinement.

- Road Construction: Produces aggregate for strong foundations.

- Demolition Projects: Breaks concrete for easy recycling.

Jaw crushers serve as a primary crushing solution for hard and abrasive materials like rocks and minerals. Popular in the mining and construction industries, they handle materials of all hardness levels efficiently and economically. Applications in industry include:

- Building Construction

- Mining Industry

- Road Construction

- Demolition Projects

- Aggregate production

- Recycling

- Metallurgy

- Mineral processing

- Chemical industries

Trusted Jaw Plates Suppliers for Durable and Reliable Solutions

Our jaw plates provide high performance, long-lasting durability, and consistent reliability. We deliver tailored solutions designed to keep your crushers running smoothly, maximizing efficiency at every step.

Unmatched Jaw Plate Durability

Our jaw plates use premium materials for exceptional wear resistance and durability, even in tough conditions.

Cost-Saving Solutions

Engineered to minimize wear, our jaw plates reduce maintenance costs and extend crusher part lifespans.

Tailored Jaw Plate Designs

We design jaw plates to match your crusher's needs, ensuring efficient performance and optimized output.

Safety and Enhanced Durability

Crafted from high-strength materials, our jaw plates ensure reliability, reduce downtime, and enhance workplace safety.

Global Reach with Local Expertise

We combine global expertise with local knowledge, delivering jaw plates that meet industry standards and regional needs.

Comprehensive Service and Support

From design to delivery, we offer complete support to ensure seamless integration and operation of our jaw plates.

Ready to step forward

3rd Floor, Diamond Complex, SH 41,

Industrial Area, Chhapi, North Gujarat,

India. 385210