We're not just building plants; we're building your business

As experienced cement plant manufacturers and suppliers, we understand your success is tied to more than just the plant itself. That's why our holistic approach includes site selection expertise and securing reliable raw materials, working as your strategic partner and being committed to helping your cement business thrive from the ground up.

15+

Years of Experience

50+

Cement Plants Built

10+

Awards Won

98%

Customer Satisfaction

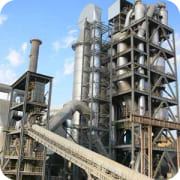

As a top cement plant manufacturer and supplier, we are committed to delivering solutions designed to maximize your return on investment. Our expertise, coupled with cutting-edge technology for cement manufacturing plants, focuses on operational efficiency to ensure your plant generates consistent profits for years to come.

Turnkey cement plant solutions

This means you will receive an operational cement production facility without managing multiple vendors or contractors. We work as a single provider for cement plant manufacturing setup, handling all aspects of the plant's design, construction, equipment procurement, installation, and commissioning.

Customized solutions and machinery offer

Transform your existing cement plant production as our team of seasoned engineers specializes in crafting bespoke modernization and expansion solutions. We work with you to understand your unique requirements and goals to upgrade your existing cement plant and unlock it’s full potential.

Raw material processing

As customized cement plant suppliers, we streamline raw material handling with automated equipment (stacker reclaimers, crushers, mills) for precise blending and energy savings. This includes using advanced systems like rotary dryers, pelletizers, and vertical mills to ensure consistent raw meal quality.

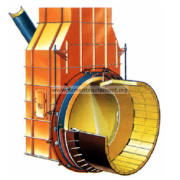

Clinker production

The clinker production solutions at NNT Cement are engineered for maximum reliability, thermal efficiency, and environmental responsibility. Our kiln systems include VSK and rotary kilns customized to your specific clinker quality requirements and production capacity.

Cement grinding & packing

Redefine your cement quality with our cement grinding and packing solutions. This ensures efficient and consistent production of high-quality cement products. Leverage our range of grinding technologies like ball mills, vertical roller mills, and automated packing and palletizing systems.

A complete range of spare parts for your cement manufacturing plant

Ensure continuous operation of your cement plant by leveraging a range of high-quality spare parts and wear components. Our inventory is stocked with everything you need to keep your plant running smoothly, from essential replacements to proactive maintenance components.

Rotary Kiln Parts

Girth Gear

Kiln Pinion Gear

Kiln Tyre

Kiln Seal

Kiln Support Roller

Ball Mill Parts

Kiln bricks

Refractory

Preheater Cyclones

Burner Pipes

Burner Nozzles

Storage solutions engineered for optimal efficiency

cement plant manufacturing company provides a comprehensive storage solutions designed to protect your inventory and streamline your operations.

Turnkey cement plant solutions

This means you will receive an operational cement production facility without managing multiple vendors or contractors. We work as a single provider for cement plant manufacturing setup, handling all aspects of the plant's design, construction, equipment procurement, installation, and commissioning.

Our expertise

At NNT Cement, we're not just engineers; we're architects of your cement plant's success. The seasoned team boasts experts having technical mastery with an intimate understanding of the cement industry. We delve deep into your unique needs to craft bespoke solutions that optimizes performance, efficiency, and profitability.

Engineering and design

Meticulously crafting custom plant designs to drive efficiency, productivity, and resource utilization. Also, we adhere to industry standards and best practices to help you stay compliant and ensure uninterrupted production.

Process optimization

We begin with analyzing your existing operations to identify bottlenecks and inefficiencies. And then, we implement data-driven solutions to boost productivity, reduce costs, and improve product quality.

Environmental compliance

We prioritize environmental responsibility by incorporating sustainable practices and technologies into your plant design. This again ensures compliance with all applicable regulations to minimize your ecological footprint.

Project management

Get comprehensive project management services from conceptualization to commissioning for seamless coordination, timely execution, and cost-effective delivery of your cement plant project.

Why choose us

If you are looking for a trusted cement plant manufacturer and supplier, NNT Cement is the answer. We offer a unique combination of industry expertise, cost efficiency, and customized solutions, all in one place, with unmatched standards and industry best practices.

Industry expertise

Leverage our decades of in-depth experience in the cement industry as our team of seasoned cement industry professionals understands the unique challenges and opportunities to drive innovative solutions and reliable outcomes.

Cost efficiency

We help optimize every function — from design to construction, and even storage with cost-effective solutions without compromising on quality. We leverage our industry connections and experience to source materials and equipment at competitive prices, passing the savings on to you.

Customized solutions

Every client has unique requirements and objectives, and hence, we provide tailor-made cement manufacturing solutions by collaborating closely with your business. We help design a cement plant that perfectly suits your production goals, budget, and site specifications.

Turnkey solution

Offering comprehensive turnkey solutions to handle every aspect of your cement plant project, from initial concept and design to equipment procurement, installation, commissioning, and ongoing maintenance. This streamlined approach reduces downtimes and contributes to a sustainable, responsible operation.

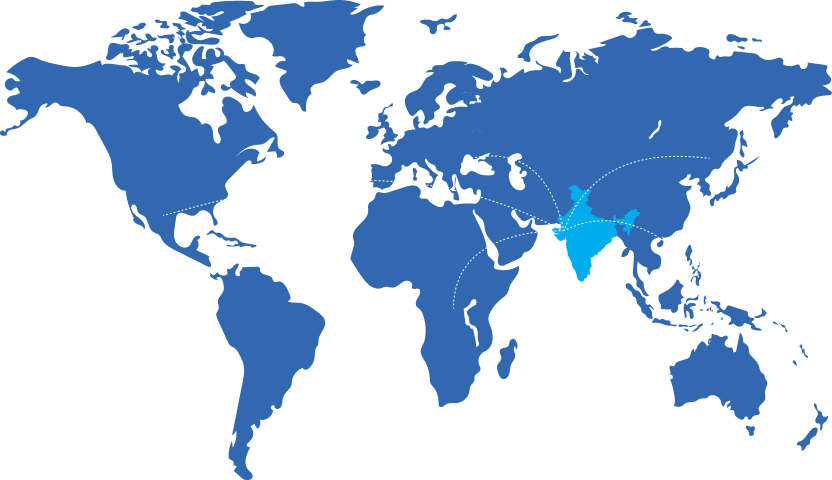

Global reach with local insight

Our team functions at a global scale to provide you with the international best practices and expertise for cement manufacturing projects. At the same time, we maintain a deep understanding of local regulations, market conditions, and cultural sensitivities to ensure smooth functioning of your cement plant.

Safety standards

We adhere to the highest international safety standards, implementing rigorous protocols and providing comprehensive and proactive risk management strategies to ensure the well-being of our workforce, your employees, and the communities surrounding your plant, leading to a sustainable, responsible operation.

Our achivements

We've consistently delivered successful cement plant projects, exceeding client expectations and setting new industry standards. Our work in the cement industry is a testament to the legacy of innovation, efficiency, and sustainable solutions.

Your global cement manufacturing partner

We run operations for cement manufacturing plants globally and have a demonstrated history of completing projects in different countries. This means you can benefit from our global expertise and experience in completing cement plant since we understand the unique challenges and opportunities in different markets of the world.

Our Blog

Browse most recent blog & news from N&T. View Engineering Procurement Construction related news,and articles.

Ready to step forward

3rd Floor, Diamond Complex, SH 41,

Industrial Area, Chhapi, North Gujarat,

India. 385210